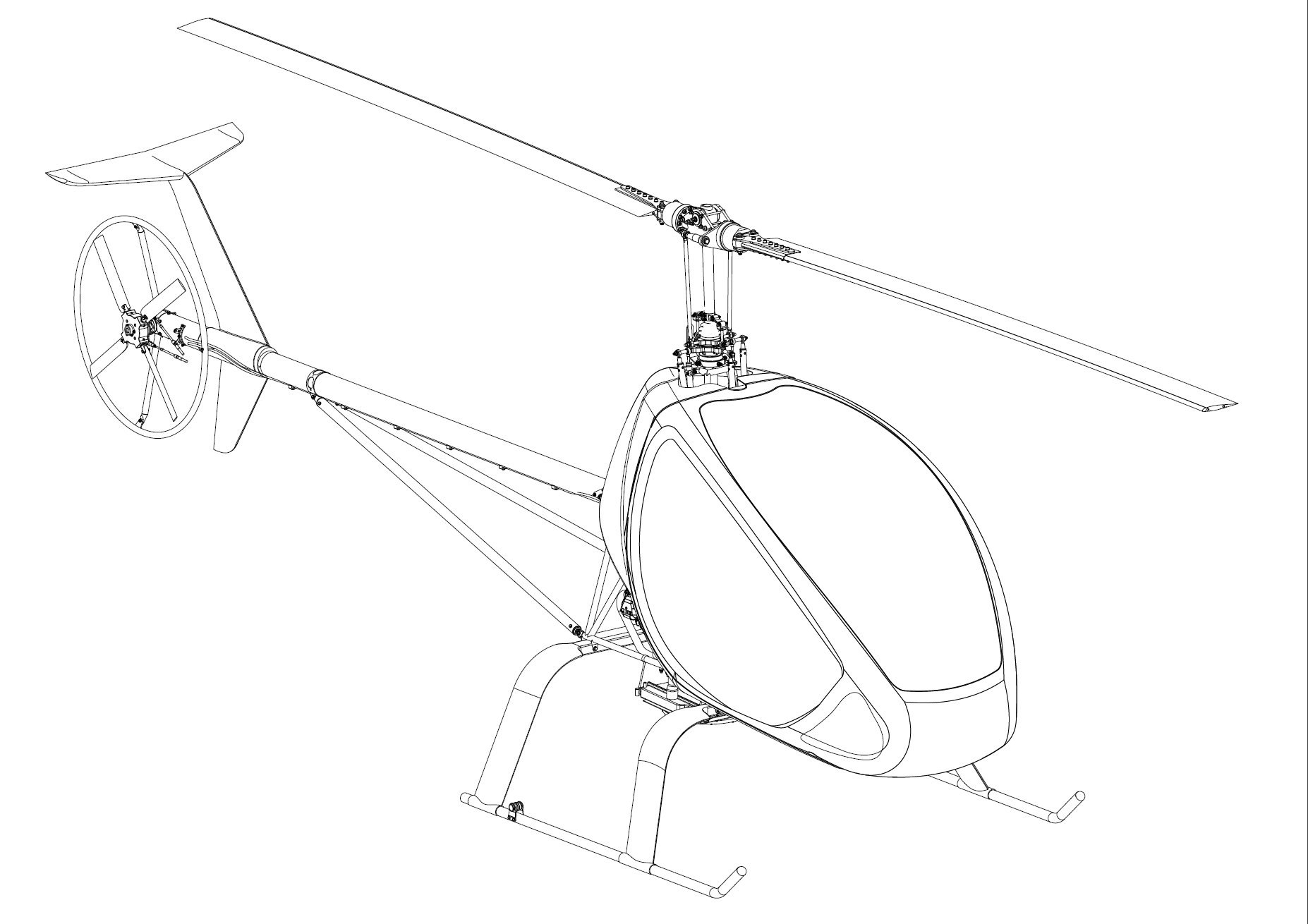

Maintenance & Operating Costs

The maintenance program for the H3 Sport is one of this machine’s greatest advantages. The entire helicopter has been designed for ease of access, simplicity and low cost of maintenance for the owner. It can be performed easily thanks to detailed but very simple technical procedures.

The general TBO of the H3 Sport is at 2400 h and has no calendar limited service life. Service inspections are spaced at every 25, 50, 100, 300, 600, 1200 and 2400 h.

The figures below are estimates only, calculated by Dynali Helicopter Company. The prices will vary depending on use, costs of labour, local condition and prices. Under no condition should the estimated costs below be considered as contractually binding.

1. Provision for Helicopter standard overhaul

2400 h helicopter standard overhaul (€ 17.640,00), per flight hour € 8,80

(Labour cost excluded)

2. Direct operating cost

| OPERATION | ESTIMATED TIME | LABOUR | PARTS |

| 50h maintenance operation cost | 5h labour (estimated) | € 350 | € 26,50 |

| 100h maintenance operation cost | 10h labour (estimated) | € 700 | € 300,00 |

| 300h maintenance operation cost | 25h labour (estimated) | € 1750 | € 1.720,00 |

| 600h maintenance operation cost | 50h labour (estimated) | € 3500 | € 6.290,00 |

| 1200h maintenance operation cost | 100h labour (estimated) | € 7000 | € 14.710,00 |

Total direct operating cost, per flight hour* € 37,70

*Cumulative direct maintenance cost on 2400h = € 75.400,00

3. Total operating cost

(1) 2400h helicopter standard overhaul, per flight hour € 8,80

(2) Total direct operating cost, per flight hour € 37,70

Provision for non-scheduled repair, per flight hour € 5,00

Total operating cost, per flight hour € 51,50

(Engine overhaul, fuel, labour, insurance, depreciation, local

transportation and hangar excluded)

Special maintenance operations

These maintenance operations can not be estimated per flight hour as intervals are indeterminate and dependent on inspection.

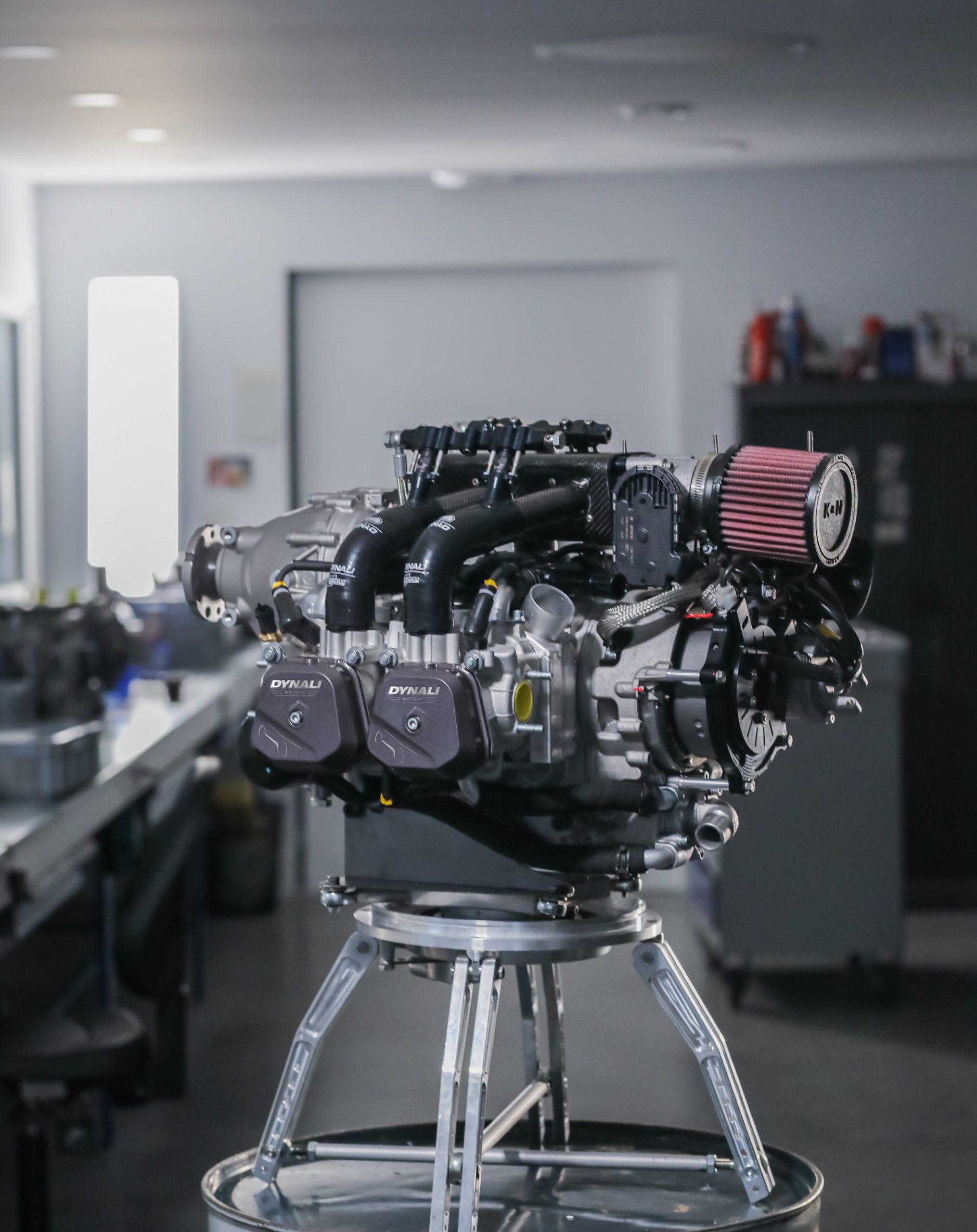

Engine overhaul Rotax (912ULS / 912ULS-I / 914UL) See Rotax Price’s list