Maintenance & Operating Costs

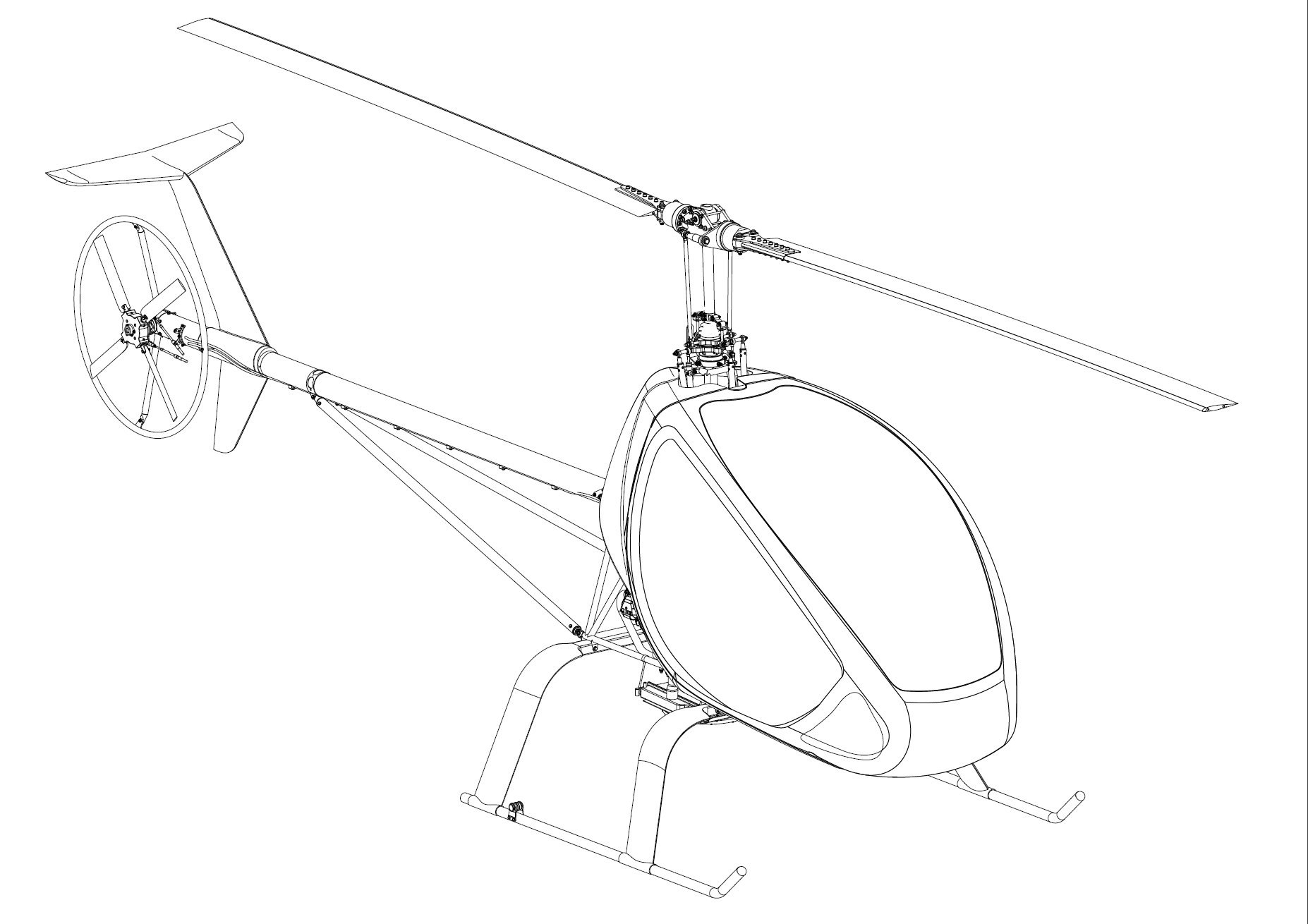

The H3 Sport maintenance program is designed to ensure the safety and longevity of your aircraft, with inspections scheduled at 25, 50, 100, 300, 600, 1200, and 2000 flight hours. Some maintenance protocols are available in the documentation section of our website.

Direct & Operating Costs

The estimated maintenance cost, including parts and labor, is €75 (excl. VAT) per flight hour, calculated over a total of 2000 flight hours.

Calculation Method:

The estimate is based on all parts listed in the maintenance manuals and the associated labor time. The total cost for 2000 flight hours was then distributed evenly over each flight hour.

Total Operating Costs

-

Direct operating cost per flight hour: €75

-

Allowance for unscheduled repairs per flight hour: €5

-

Fuel consumption (22 L/h): €40

Total operating cost per flight hour: €120

(Insurance, depreciation, facilities, transportation, and hangar costs are excluded.)

Additionnal Maintenance Information

Please note that the lifespan of certain components depends on factors external to their manufacturing process, such as aircraft storage conditions, usage, and pilot flying style. This is why our maintenance protocols include regular inspections to determine whether replacement is required.

- TBO (Time Between Overhaul) for the rotor: 1200 hours

- Main Transmission Gearbox (BTP) and Rear Transmission Gearbox (BTA) are inspected every 300 hours

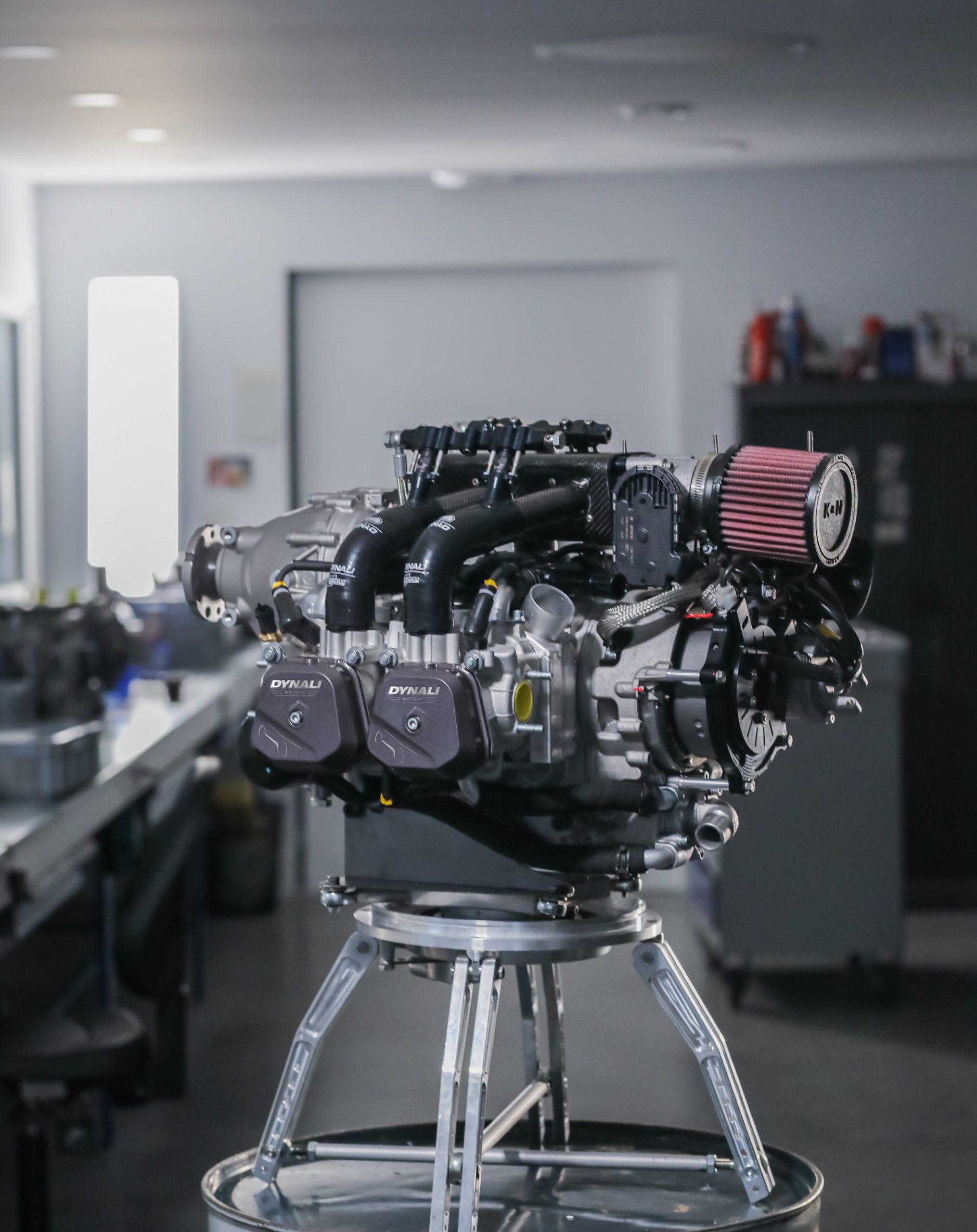

- Engine overhaul required at 1200 hours

- We offer several levels of maintenance training, tailored to the needs of each user.

- Professional tooling is essential. Dynali has developed specific tools to simplify certain maintenance procedures. For more details, please refer to the maintenance protocol available on our website.